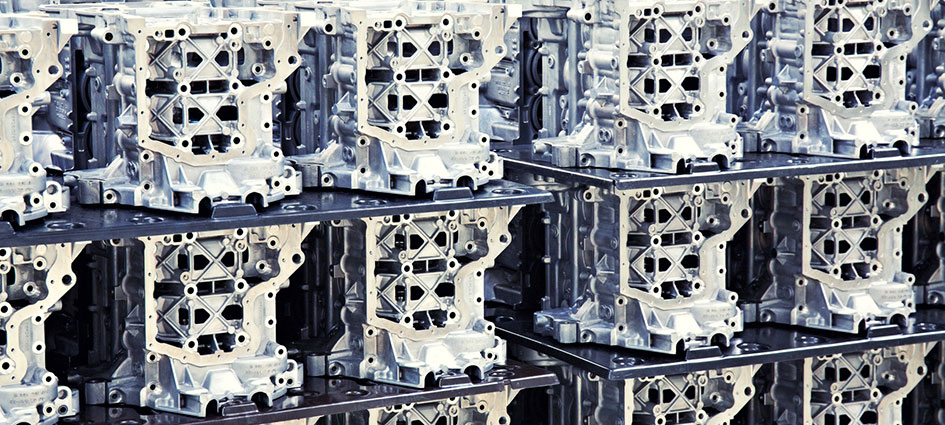

Die Casting & Permanent Mold

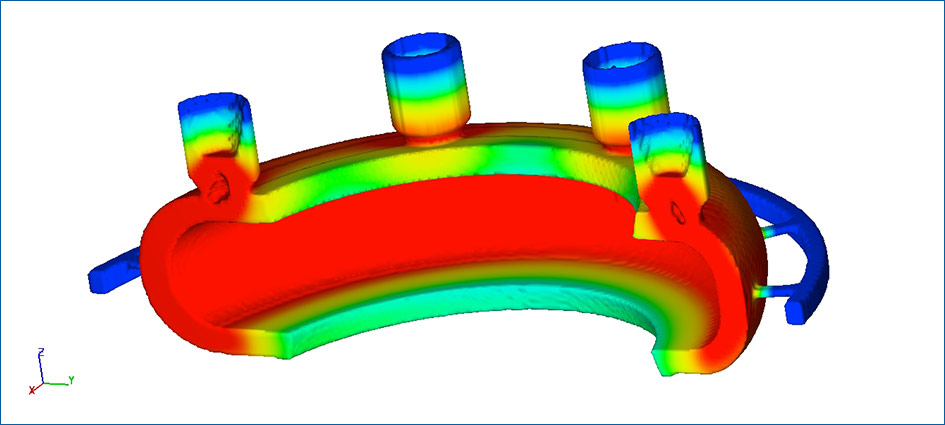

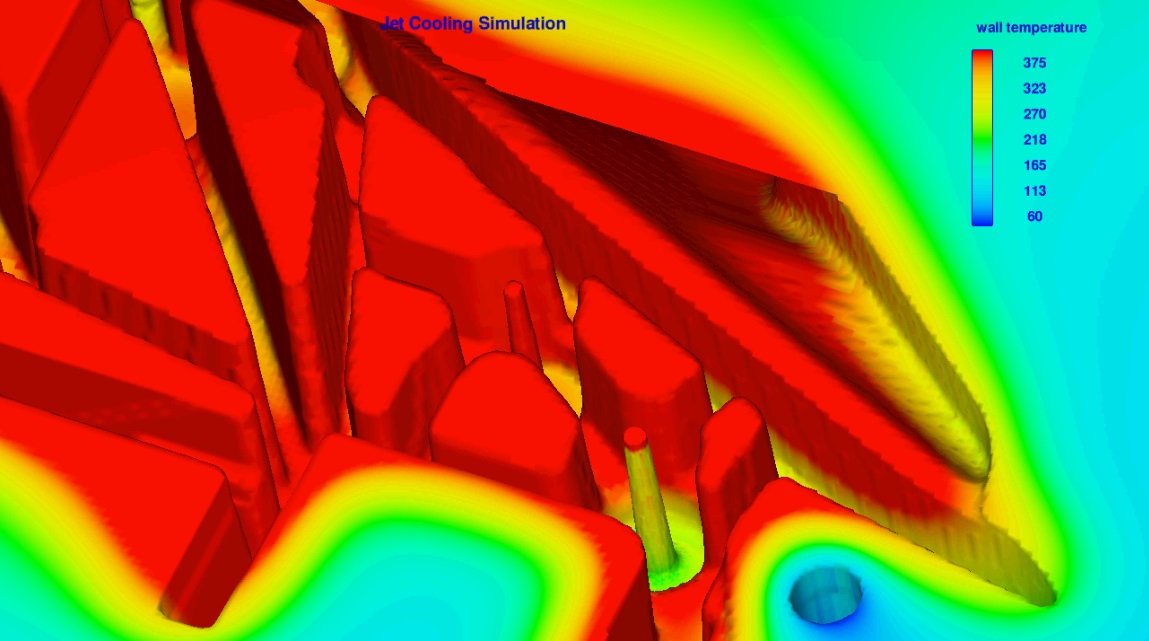

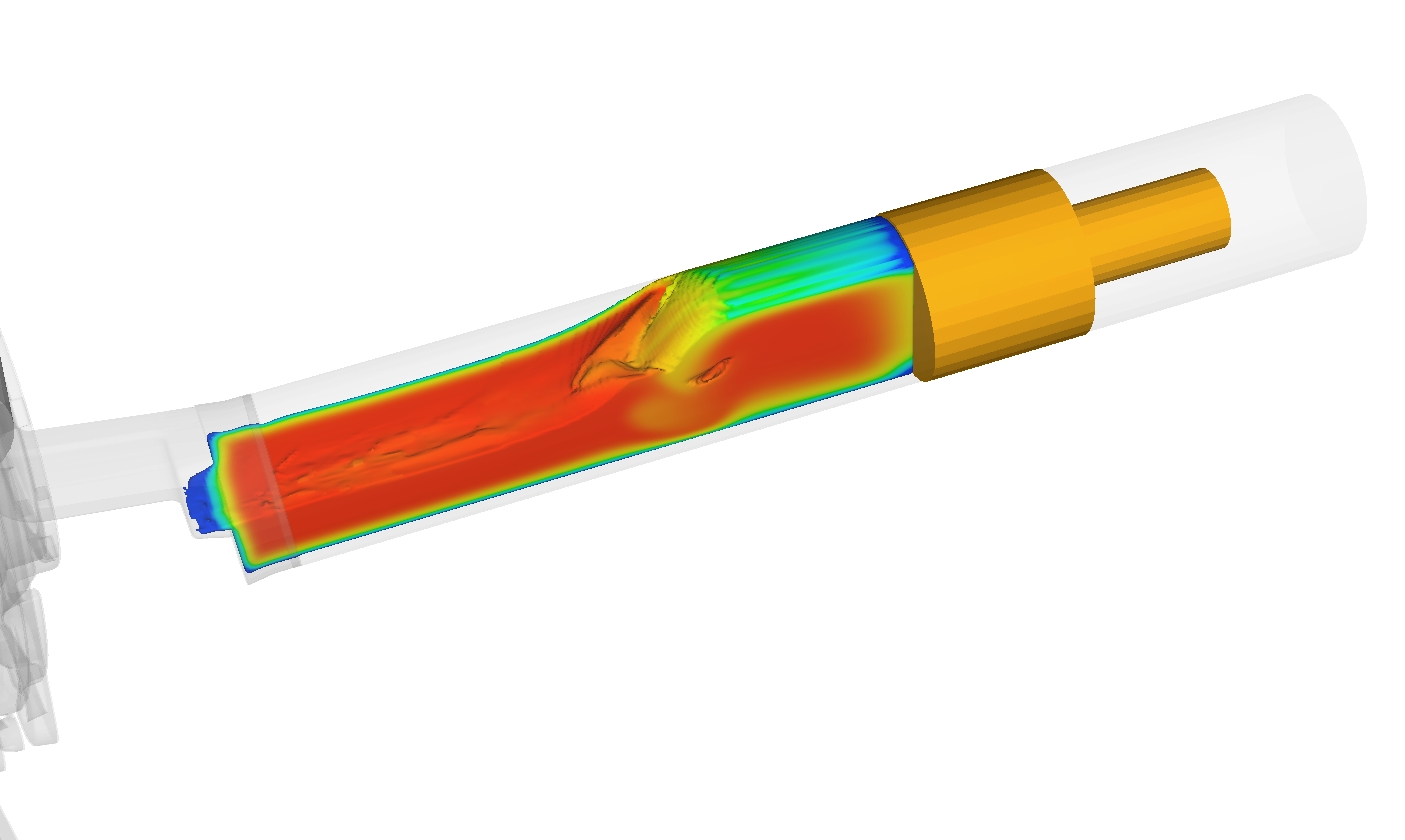

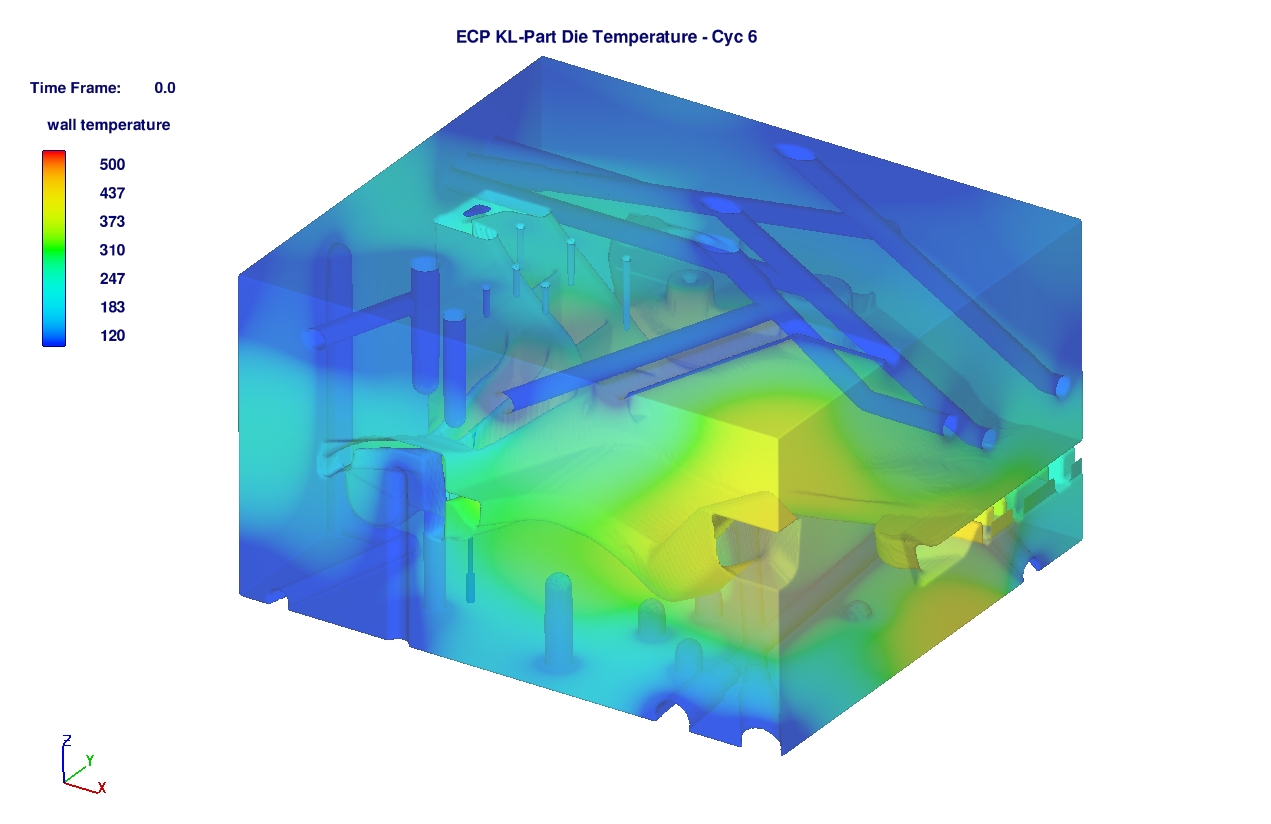

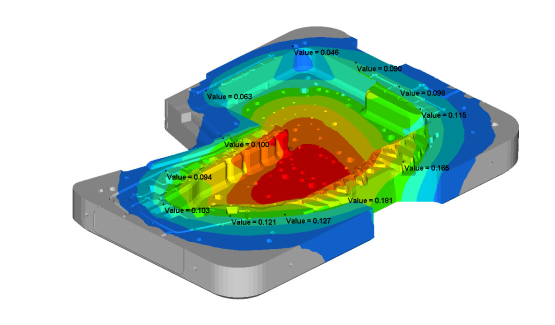

We believe that all casting processes can be brought down to a predictable science

Bholster Technologies is a Canadian owned company dedicated to providing optimized gating and cooling solutions backed by accurate and realistic simulations of fluid flow, heat transfer, solidification and gas entrapment. We are a virtual lab where your design ideas are tested and optimized.

Our mastery of the fundamental science of casting enables us to simplify by eliminating the negligible and irrelevant. BHOLSTER has consistently delivered practical solutions that worked exactly as predicted!